24/7 Emergency Call Now

(310)433-9652

24/7 Emergency Call Now

(310)433-9652

Indirect Heated, Gas Fired Oven

Scenario:

Customer requested an oven which used indirect heated, gas-fired, and designed at 1100°F +/- 10° degrees.

Solution:

West Coast Combustion designed a 321 stainless steel heat exchanger with a combustion system which conveyed hot gases through the inside of the heat exchanger. A fan was installed to remove the heat from the outside of the heat exchanger for heating the oven.

High Pressure Heater

Scenario: Customer is a testing facility for different industries. They required a piece of equipment that could test multiple round parts of varying diameters with 250-1000scfm of air volume at 1000-2500 degrees Fahrenheit and at 0-8 psig.

Solution: WCC designed and manufactured a custom direct fired air heater that utilizes a positive displacement blower for air supply. The blower is controlled by a VFD that allows them to provide a specific air volume while the supply pressure is dictated by the size of the part being tested. The heater is supplied with a constant flow and simply modulates its fuel control valve in order to obtain the desired air temperature. The customer has since tested aerospace parts for R&D purposes for their customers.

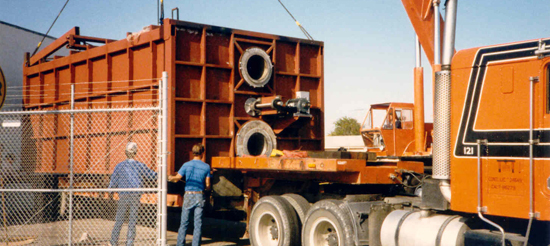

Thermal Oxidizer

Scenario:

The client is a plastic factory. Thermal oxidizers were located on opposite ends of their plant. Due to an extremely polluted VOC supply,and units that were almost 25 years in service were in horrible condition. WCC was approached by the customer who needed 2 new thermal oxidizers and a fast turn around.

CATALYTIC AFTERBURNER

Scenario: Customer is a large volume bakery. The SCAQMD air district in Southern California required them to install an afterburner on their Pita line to remove the ethanol that results from the baking of their pita bread.

Solution: West Coast Combustion designed and manufactured a custom catalytic afterburner to bring them into compliance with SCAQMD. The afterburner uses four platinum based catalyst blocks to burn off the ethanol from the air stream. This along with a low emissions burner results in maximum energy efficiency. The afterburner is controlled by a PLC with an accompanying HMl. The Afterburner communicates with the oven in order to coordinate the transfer of the oven exhaust into the afterburner. ln order to maintain compliance with SCAQMD, the afterburner does not allow for baking to begin until its catalyst are at the proper temperature needed to achieve a complete burn off of the ethanol.

All rights reserved West Coast Combustion © 2000 – 2022